Bearing Fluting

here are many issues your electric motor might experience, but one of the most common is bearing fluting. Although not a dire problem if addressed promptly, it can affect your motor’s or application’s performance.

Quickly Search for an Mechanical Equipment you are looking for:

Request a Quote

Get in Touch

Get started with our simple, proven AES Repair Process

Once we have received your item for repair, we will receive the item in our system.

1Our quoting specialists will evaluate your item and determine the parts and labor necessary to complete the repair.

2Following your approval, we will get to work on your repair. One of our repair technicians will troubleshoot the problem(s) with the item.

3To ensure the highest level of quality throughout the repair process, we comply with ISO 9001:2015 Certified QMS standards, and an ESD program.

4Once the repair is complete, we safely package your item and prepare the item for delivery or shipment.

5Our Partners and Brands We Repair

All product names, trademarks, brands and logos used on this site are the property of their respective owners. The depiction, description or sale of products featuring these names, trademarks, brands and logos is for identification purposes only and is not intended to indicate any affiliation with or authorization by any rights holder.

How Is Bearing Fluting Caused?

Traditional motors and variable frequency drives that convert AC to DC voltage come equipped with a component referred to as an insulated gate bipolar transistor that makes switching between voltages more efficient. However, there is a downside to the increased efficiency that leads to bearing fluting. The fast-switching time between currents increases the common-mode voltage the motor shaft experiences, which is then eventually discharged through your motor bearings.

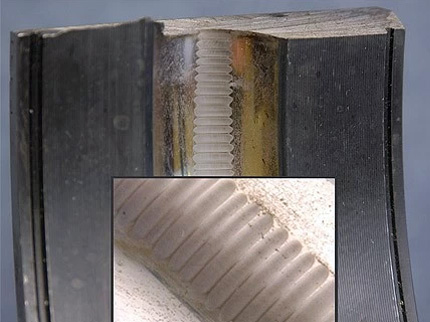

This electrical discharge leads to the grooved and frosted pits found in bearings known as bearing fluting. Although bearings are designed with lubrication to minimize the amount of fluting that occurs, even the best ones will eventually experience some fluting as the lubrication’s strength fails and extra energy discharges.

What Are Some Signs of Bearing Fluting?

Aside from the noticeable signs of bearing fluting, like the washboard-type grooves found in the bearing raceway, one of the most apparent signs of an issue is loud noises. If your motor is unusually noisy, your bearings could be caused by traveling over this damaged area. There can also be electrical damage caused by the discharges, although this is much harder to detect.

How Can I Prevent Bearing Fluting?

There are some steps you can take to minimize the damage caused by bearing fluting. These steps include using shielded cables, insulated bearings, grounding your motor’s shaft, or employing grease to conduct motor shaft currents to the ground. There are also shields and filters you can use to reduce the chances/effects of bearing fluting.

Need help? AES is here to take care of you. Contact us at (866) 386-1001 or request a quote today.