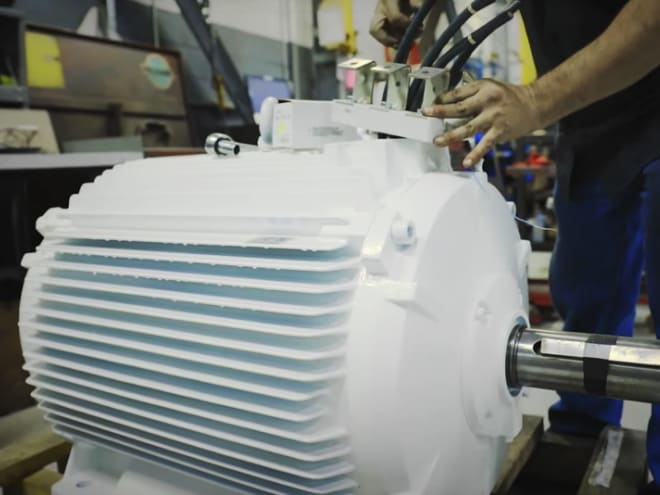

At AES, our expert mechanical technicians can repair AC/DC motors, servo motors, vacuum pumps, blowers, gearboxes, positive displacement pumps, centrifugal pumps, specialty motors, and more. AES can tackle all of your hydraulic repair needs too, from pumps to motors to valves to cylinders. Our team has all the needed knowledge, tools, and experience to provide fast, reliable repairs which are more cost-effective than seeking service from the manufacturer!

Our Offerings in Mechanical Repair

Water and electric motors don’t usually mix, so special measures are called for when you’re trying to operate motorized systems in wet or damp environments. In some way, the motor needs to be shielded against moisture and contain weep holes and other methods for moisture to escape the motor enclosure. Heating elements may also be called for to dry the motor and/or keep it warm in cold environments.

There are several options for doing this, with various levels of effectiveness. In most cases, the best choice is a washdown motor – a motor specifically designed to be waterproofed, which can even be hosed down for cleaning. However, there are other options; sometimes, you may have to make do with what you have and adapt it to fit the climate.

In this article, we’ll discuss the benefits and construction of washdown motors and other ways of staying powered in wet environments.

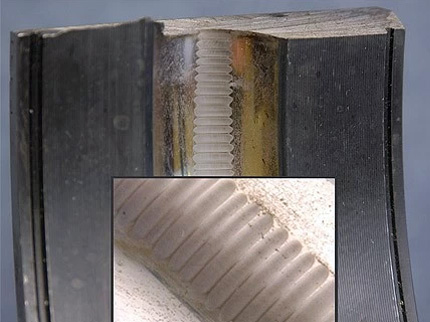

here are many issues your electric motor might experience, but one of the most common is bearing fluting. Although not a dire problem if addressed promptly, it can affect your motor’s or application’s performance.

For every engineering application that calls for a motor, you have numerous options – and one of the most fundamental questions is whether to utilize a standard general-purpose motor or use a more modern inverter duty motor instead. This isn’t merely a question of price vs. performance – these two types of motors have significantly different functions and purposes, so choosing the right one for your application is vital.

The best way to find the right motor for your project is to ask motor experts, but here are some basics of choosing between the two motor types.

Out of the many types of motors in the world, one of the most basic differences is whether they run on Alternating Current (AC) or Direct Current (DC). This can significantly impact how the motor performs in numerous ways and the electrical system that supports it, so it should be one of the first decisions made when considering a purchase.

Electric motors are used to drive or produce force for a whole host of industrial machinery applications. Eventually, even a heavy-duty motor will wear down and require some service. Has your electric motor stopped working? Replacement likely isn’t your best option; let the service pros at AES help! We specialize in electric motor repair & rewinding, and we can take care of your equipment needs, too!

Not only that, our experienced and trained technicians are ready to help you with commercial and industrial electric motor repair services at the most competitive rates in the industry. We cover Mount Airy, Winston Salem, High Point, and all the other cities of North Carolina and surrounding areas.

Stepper motors are crucial assets for machines and devices used in both commercial and industrial environments. But what happens when your stepper motor stops “stepping,” and is no longer turning properly? Time to reach out to the service pros at AES! AES has provided effective stepper motor and servo repairs for decades, and we can take care of your specific needs, too!

Vacuum pump motors are an important component of many industrial manufacturing processes. Industrial vacuum pumps help create and maintain vacuum wherever it’s needed. But if your vacuum pump has gone on the fritz, replacement isn’t your only – or even your best – option. The service pros at AES can help! We know how to work on industrial pumps, and we can take care of yours, too!

Spindle motors are the driving force for many CNC machines and other industrial machine equipment. But what happens when your spindle motor won’t turn properly, or simply stops spinning altogether? Don’t just assume you need to replace it; reach out to the service pros at AES! Spindle motor and servo repairs are among our specialties, and we can take care of your motor repair needs, too!

Crane operations are an important facet of many commercial businesses and industrial facilities. But if there’s a problem with your crane motor or hoist mechanism, you simply may not be able to get your heavy loads where they need to go. Thankfully, AES has a complete machine shop for repairing crane motors and hoist assemblies. We can get your crane lifting and lowering again!

If your business relies upon industrial motors, drives, and servos to get things moving, motor brakes and brake motors are also necessary parts of the equation. But if your brakes aren’t braking, you may need some brake coil service! AES has a complete machine shop for brake coil repairs, brake coil rewinding, brake rebuilding, and whatever else you may need.

If your business entails moving a lot of materials down the pipe, then you probably rely upon some heavy-duty industrial pumps. But what happens when your pump motor stops working and nothing’s moving? Time to call AES! AES has been providing effective repairs for motors and pumps of all types for years, and we can take care of your needs, too!

If lifting, moving, and relocating heavy items or equipment is a requirement for your business, the chances are good that you depend upon a hoist or crane mechanism. But if your hoist has stopped hoisting, then your productivity can also grind to a halt! AES has a complete machine shop for repairing hoist assemblies and the motors which drive them. We can restore the lift to your hoist!

Commercial businesses and enterprises rely upon heavy-duty motors and drives to be able to power their essential equipment, and gear reducers are an important component of these connected systems. But if there’s a problem with your gear reducer, then your machinery won’t be able to do its job properly. AES has a complete machine shop for repairing gear reducers and other essentials; we can take care of you!

Just as heart valves conduct blood where it needs to go, industrial valves do the same for essential liquids and gases utilized by industrial machinery and equipment. If there’s a problem with your system, a faulty valve or valves could very well be the culprit. Thankfully, AES offers comprehensive valve repair and replacement services for all sorts of electric, hydraulic, and pneumatic applications!

Many businesses and industries rely upon some pretty powerful motors to drive their essential vehicles, machinery, & equipment. These motor systems also rely upon gearboxes to help transfer power where it’s needed. But if your gearbox breaks down, then so does your equipment! AES has a complete machine shop for repairing every sort of motor and connected gearbox; our skilled repair technicians can take care of your needs!

AC/DC electric motors are the essential driving source of power for many industrial and commercial machines & applications. But if your motor stops working, then so does your equipment – and nobody has time for that! AES has provided effective AC/DC motor and servo motor repairs for satisfied clients for years, and our skilled repair technicians can take care of your needs, too!

Mechanical Equipment

Industries We Serve in Mechanicals!

Our Partners and Brands We Repair

All product names, trademarks, brands and logos used on this site are the property of their respective owners. The depiction, description or sale of products featuring these names, trademarks, brands and logos is for identification purposes only and is not intended to indicate any affiliation with or authorization by any rights holder.

Reliable Mechanical Equipment Repair for Less

No matter what type of business or organization you run, and no matter what industry in which you operate, AES can help to save you money! Sooner or later, all types of industrial equipment break down or just need some service. Sure, you could just pay to replace those items, but that can get incredibly expensive in a hurry. Wouldn’t it be great if there were a more affordable solution available to you?

With AES, there is a better solution! Why pay to replace an expensive piece of mechanical or hydraulic equipment when you don’t have to? And why go through the hassle of trying to enlist service from the original manufacturer, when there’s a better alternative? The trained team of experts at AES can repair and/or refurbish your mechanical and hydraulic equipment for less, AND we can do it faster! Not only can we get your essential machinery up and running again, we can also save you some money in the process!

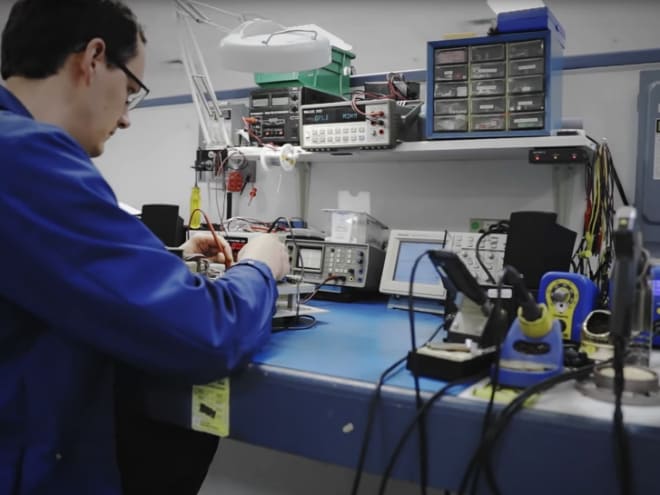

Trained, Experienced Mechanical Technicians Who Can Take Care of Your Needs

When it comes to delivering effective repairs for your mechanical and hydraulic items, you won’t find a better-equipped team in the business. At AES, we take the quality of our services and workmanship very seriously! Not only does our team possess a wealth of industry experience, but we also provide them with ongoing training opportunities so they can continue to hone their craft. And even if you bring us a specific item we’ve never worked on before, our in-house team of engineers is here to help us both diagnose your problem and figure out the best way to address it.

And we’re not the only ones who are confident in our team’s abilities, either. A host of major manufacturers also recognize our capabilities, and have designated AES as a factory-authorized industrial repair center. Here’s just a sampling of the many brands who have chosen to designate AES as an official repair partner:

- Baldor/Reliance Motors and Drives

- US Motors

- Siemens Global

- Lincoln Electric Motor Technologies

- Leeson Motors and Gearmotors

- Hyundai/Worldwide

- Permco Hydraulics

Since all of these brands trust AES to work on their products, you can trust us to take care of your specific repair needs, too!

AES – Quality Repair Service with a Fast Turnaround Time

The fact of the matter is that quality mechanical equipment repair takes time if you want it done right. The last thing you want is a rushed job that doesn’t really fix your problem! Proper testing, diagnosis, repairs, and refurbishment are all essential if you want your equipment to be able to work as good as new. The good news is that AES doesn’t cut corners, and our team never misses any important steps.

But here’s the even better news. Not only can our full slate of trained professionals get your job done right, we can also get it done and get your equipment back to you faster. If what you really need is a time-sensitive solution, nobody is better equipped to accept the challenge than AES! We offer a fast turnaround time of 8-10 business days for most standard projects, and we also give you the option of choosing a RUSH turnaround time of 1-3 business days, if that’s what your timeline dictates! If time is really of the essence when it comes to getting your mechanical or hydraulic equipment back online, AES has you covered!

The Best Warranty in the Industrial Mechanical Repair Business!

When you choose to partner with AES, that’s how we choose to see you – as a partner! We’ll work to build a real relationship with you, and we’ll assign an individual account manager and account specialist to focus on your project. At AES, quality of repair service and quality of customer service are both equally important to us.

And here’s another game-changer to keep in mind. We believe in the value of what we have to offer, and we stand behind everything we do. In fact, we’re so confident in the level of our workmanship that we provide an industry-leading 24-Month Limited Warranty for ALL REPAIRS! If a problem arises within that time frame which is a result of an AES workmanship issue, we’ll provide follow-up service to fix the problem at no additional cost! How’s that for service you can trust?

Trust AES for All Your Mechanical Repair Service Needs

AES has been providing quality industrial mechanical repair services since our founding in 1992, and mechanical & hydraulic repairs continue to remain a hallmark of AES today. And while we’ll always remain committed to providing needed repairs, we’ve also expanded our service offerings to now include the sale of both new and used industrial equipment components, in order to better meet our customers’ needs.

Looking for a specific part or replacement? Our searchable marketplace includes THOUSANDS of respected supply vendors! We are happy to provide this service to source new and used replacements in a fast, efficient, and cost-effective manner for the benefit of YOU, our customers. You can trust AES with your mechanical equipment repairs, and now you can trust us with your industrial mechanical surplus needs, as well.

Having trouble finding the item you need? Just fill out our Request a Quote form, shoot us an email at sales@aesintl.com, or give us a call at (866) 386-1001. We’ll do our best to help you get what you need, as we always strive to provide you with the best solutions for you, and for your business or organization!

Ready to get your mechanical equipment up and running again? AES is here to help! Reach out to us today!

Latest Articles & Videos on Mechanical Repairs